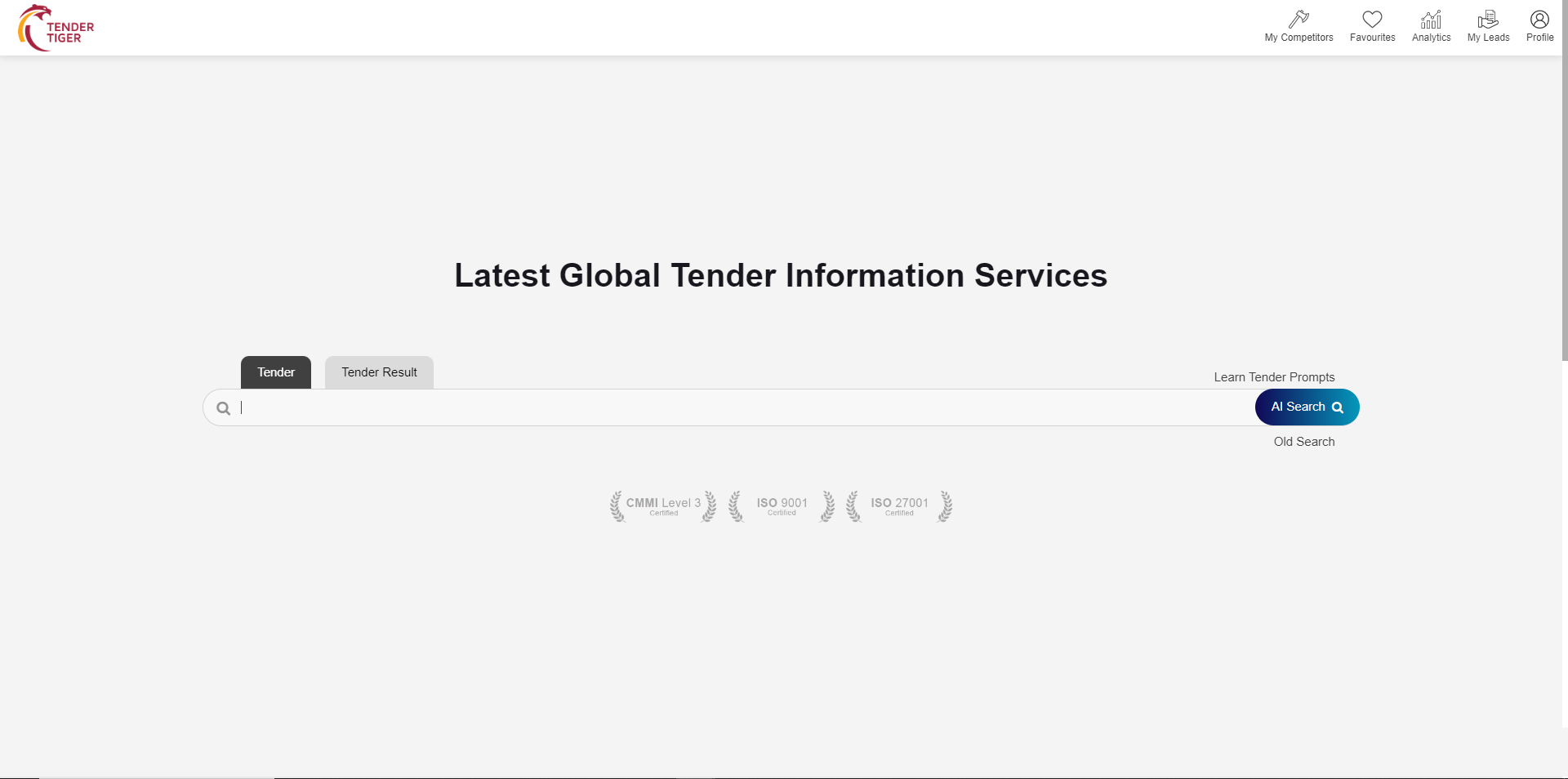

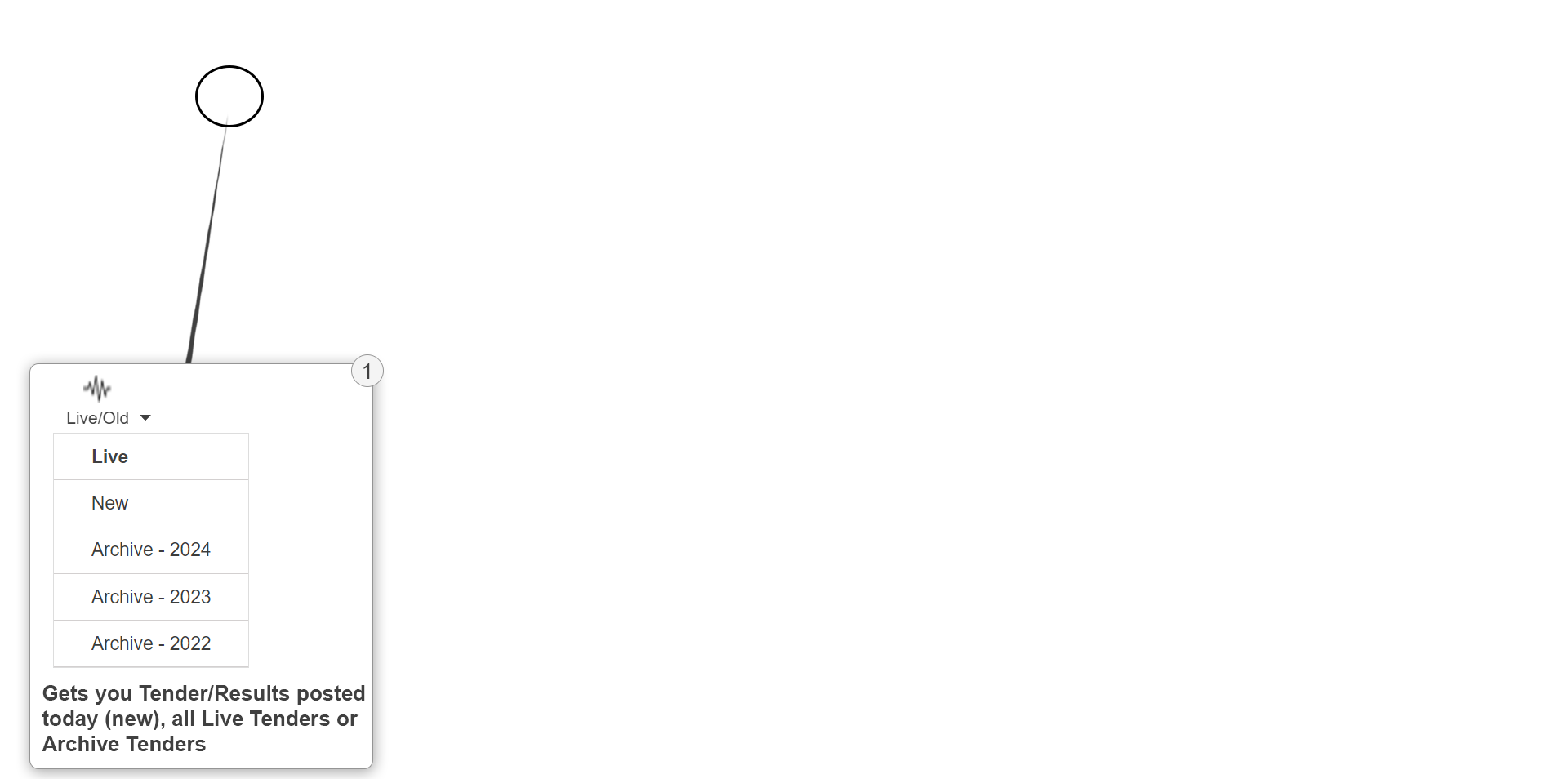

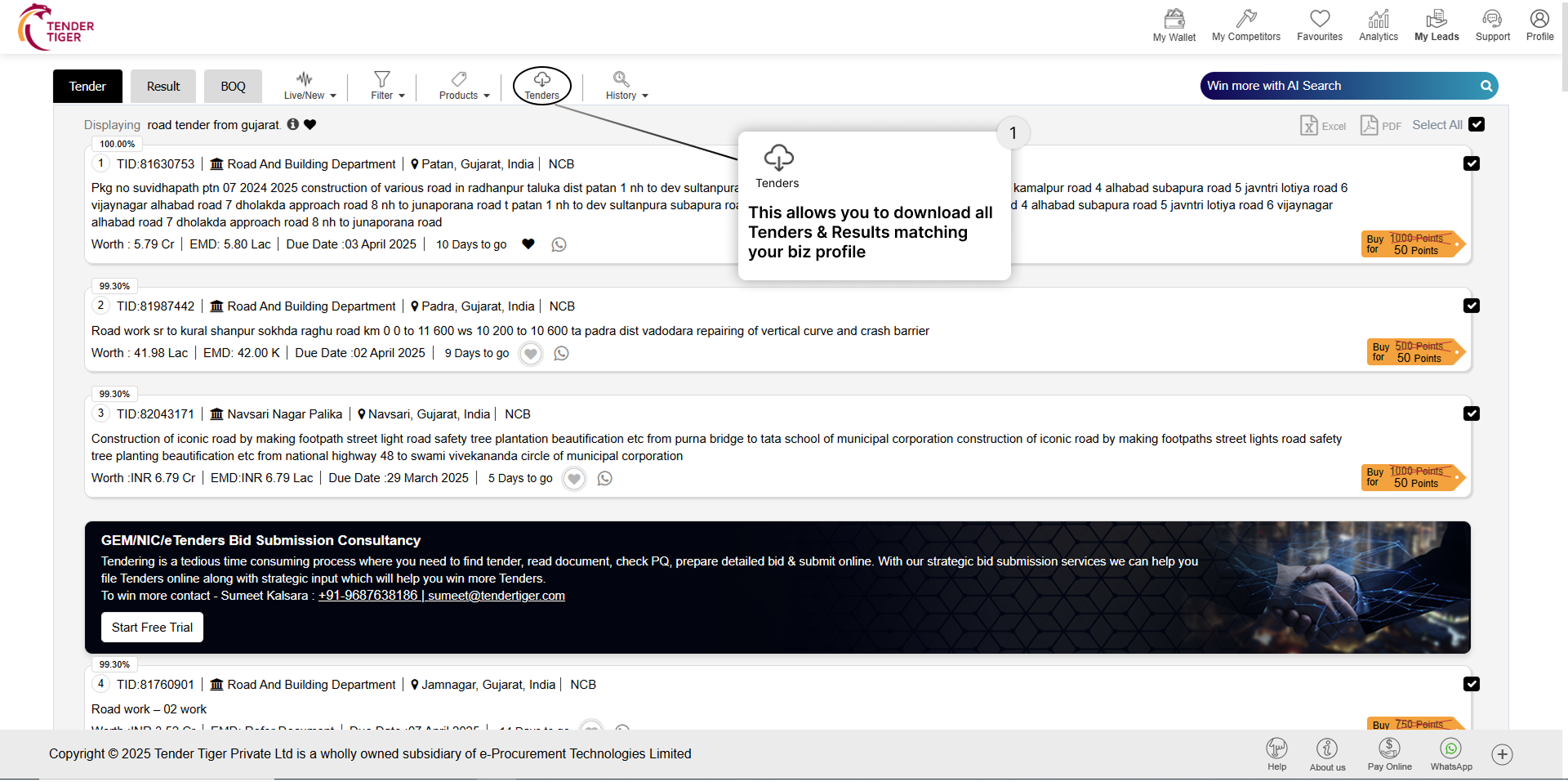

Live/Old

Live/Old

- Live

- New

- Archive - 2025

- Archive - 2024

- Archive - 2023

- Archive - 2022

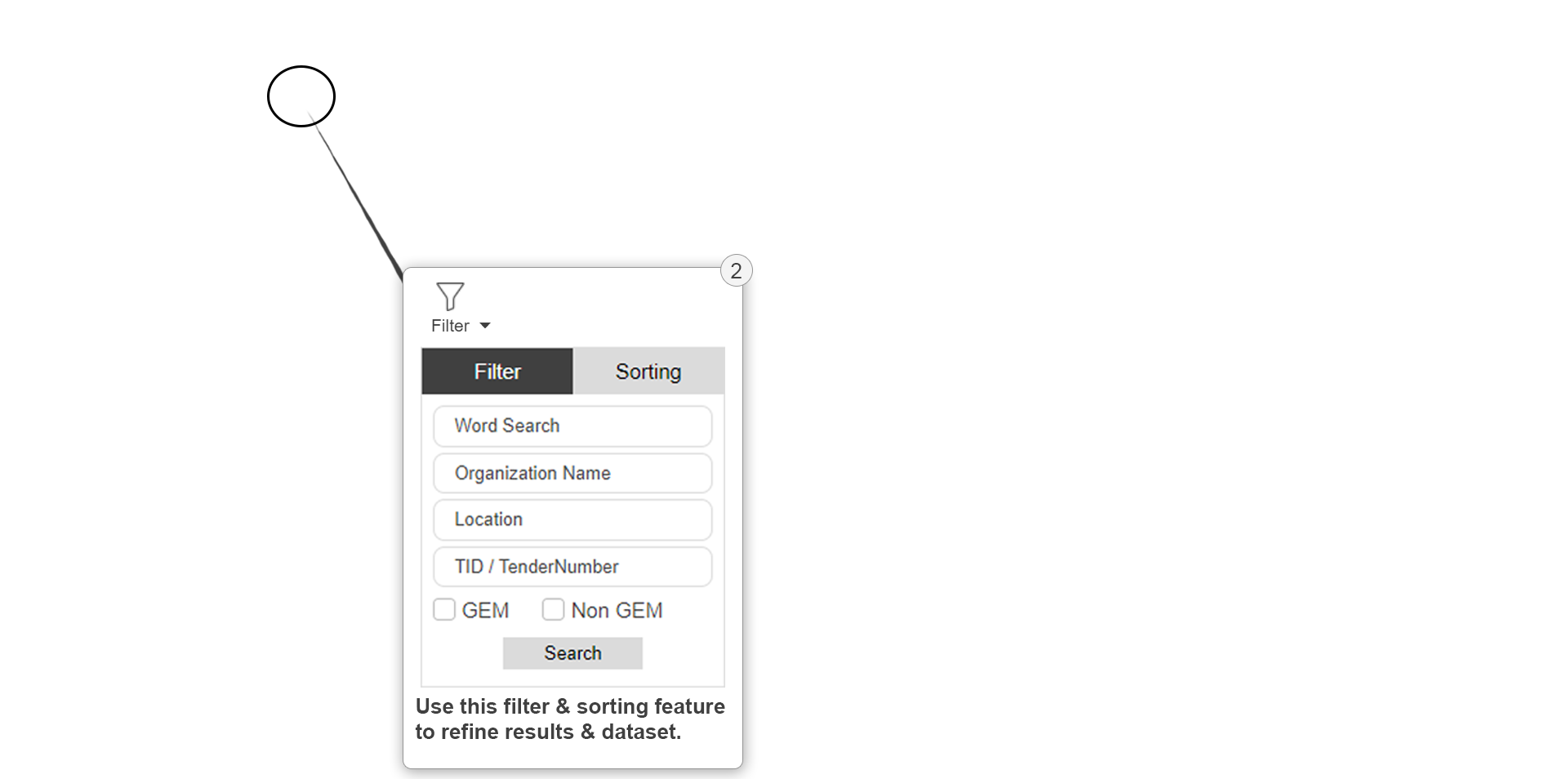

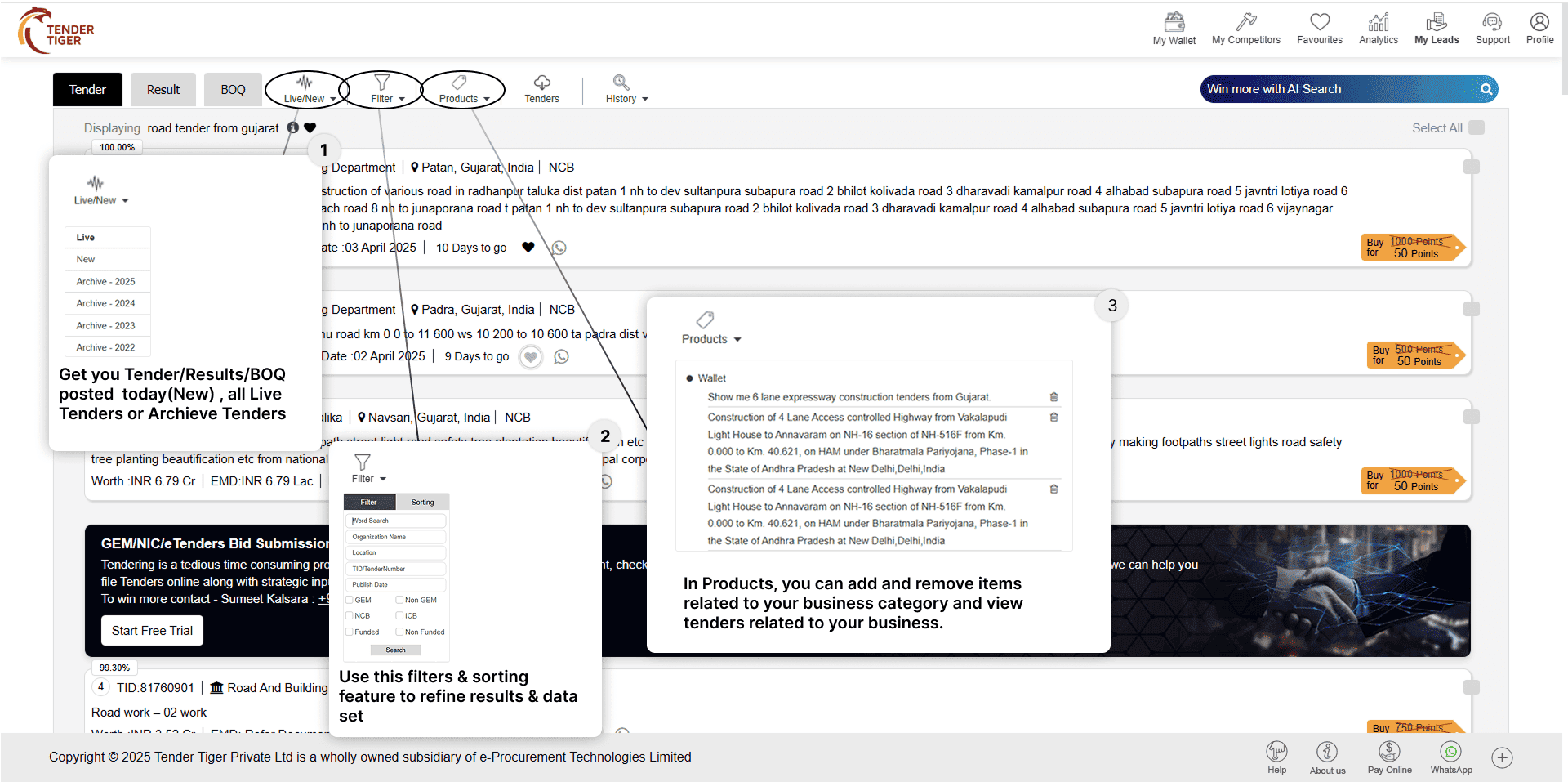

Filter

Filter

History

History